Carbon monoxide CO removal catalyst with Noble metal

product parameters

| Ingredients | AlO and palladium (Pd) |

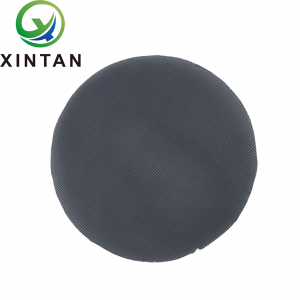

| Shape | sphere |

| Size | Diameter: 3mm-5mm |

| Bulk density | 0 . 70~ 0 . 80g/m l |

| Surface area | ~ 170m2/ g |

| GHSV | 2.0~5.0×103 |

| Reaction o f CO content in tail gas | < 1ppm |

| Working temperature | 160-300℃ |

| Working life | 2-3 years |

| Operating pressure | <10.0Mpa |

| Loading ratio of height and diameter | 3:1 |

The formula to calculate required quantity

A) Based on CO and H2 concentration,airflow and working temperature and humdity.

B) Volume of catalyst=Airflow/GHSV.

C) Weight of catalyst=Volume*Bulk specific gravity(bulk density)

D) Xintan can offer professional advice on the quantity needed

Loading tips

The pressure drop of catalyst bed in industrial plant i s closely related to the ratio o f height to diameter o f catalyst bed , the size of gas flow, the porosity of gas distribution plate , the shape and size of catalyst particles , the mechanical strength and the operating process conditions. According to our experience, the ratio of height to diameter of catalyst bed is controlled at about 3:1.

Pay close attention to the effect of bubble and acid mist when using and storing the catalyst. When filling, first lay a layer of stainless steel wire mesh (aperture is 2.5 ~ 3mm), and then place a layer of about 10cm thick ceramic ball (Ø10 ~ 15mm); A layer of stainless steel wire mesh is placed on the upper part of the ceramic layer as the support of the catalyst bed, and then the catalyst is loaded. When loading, the relevant personnel must wear dust masks, and the height of the catalyst free fall should not be greater than 0.5 meters. Lay a layer of stainless steel wire mesh on top of the packed catalyst bed, and then place a ceramic ball (Ø10 ~ 15mm) with a thickness of 10 ~ 15cm.

The catalyst does not require reduction treatment before use.

Shipping,Package and storage

A) Xintan can deliver cargo below 5000kgs within 7 days.

B) 1kg into vacuum package.

C) Keep it dry and seal the iron drum when you store it.

Applications of CO removal catalyst

Specially used for CO and H2 removing in CO2, It can convert CO into CO2 through oxidation and convert H2 into H2O Application is safe and energy free.