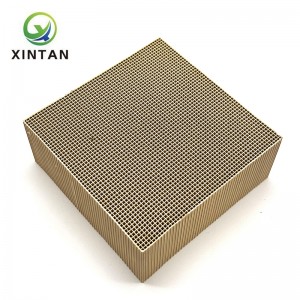

Honeycomb CO removal catalyst

Honeycomb CO removal catalyst uses cordierite honeycomb ceramic as a carrier and is a highly active catalyst prepared from a variety of rare earth metals. The catalyst produced by Hunan Xintan has the characteristics of high structural strength, strong surface coating adhesion, and is not easy to fall off. This catalyst can not only be used to treat carbon monoxide in flue gas, but also has high catalytic performance in chlorine-containing working conditions, and can be used for the treatment of chlorine-containing organic waste gas, and is widely used in the treatment of steel flue gas, lime kiln flue gas, waste incineration smoke and other smoke.

Main parameters

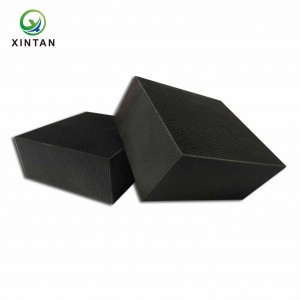

| Appearance | Black honeycomb |

| Ingredients | Mn, Zr, etc. |

| Carrier | Cordierite honeycomb ceramic, square, 200cpi |

|

Size |

100 x 100 x 50mm or customized |

| Bulk density | 560 g/L ± 50 |

| Total active load | 50~60g/L±0.5 or customized |

| Recommended GHSV | 8000~20000h-1 (depends on the working conditions) |

| Recommended wind speed | <1.5 m/s |

| Working temperature range | 120~350℃ |

| Maximum short-time temperature resistance |

600℃ |

| Efficiency |

>95% |

| Compressive strength | ≥10MPa |

| Desorption temperature | ≤120℃ |

| Service life | 2-3 years |

Shipping,Package and storage

A)Generally, the products need to be customized, and we can deliver the cargo within 8 working days.

B)The products are packed in cartons.

C)Pls avoid water and dust, sealed at room temperature when you store it.

Applications of Honeycomb CO removal catalyst

CO removal catalyst (Honeycomb) is specially used for carbon monoxide in flue gas, and does not contain halogen, sulfur and excessive dust, which affect the exhaust gas treatment. It is widely used in the treatment of steel flue gas, lime kiln flue gas, waste incineration flue gas and other flue gas.

Remark:

A)Avoid water and dust when storing, and seal at room temperature.

B)The waste gas shall not contain sulfur, phosphorus, arsenic, lead, mercury, other halogens other than chlorine (fluorine, bromine, iodine, astatine), heavy metals, resins, high boiling point, high viscosity polymers and other toxic chemical elements or substances;

C)The catalyst should be handled lightly, and the direction of the catalyst hole should be consistent with the direction of the air flow when filling, and should be placed closely without any gap;

D)When the activity of the catalyst decreases for a long time, the catalytic bed can be switched back and forth or up and down, or the working temperature of the catalytic chamber can be appropriately increased;

E)The catalyst should be moisture-proof and not soaked or washed with water.