Hopcalite Catalyst/Carbon monoxide (CO) Removal Catalyst

product parameters

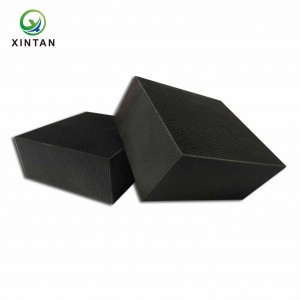

| Appearance | Black or dark brown particle or powder |

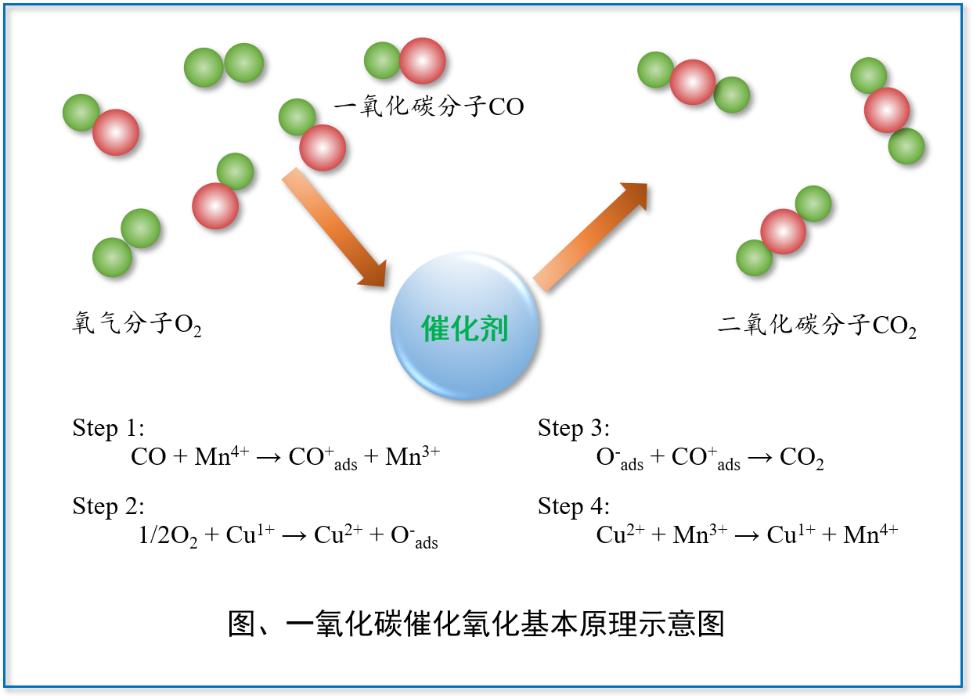

| Ingredients | MnO2, CuO |

| MnO2:CuO | 1 : 0.8 |

| Diameter | Φ1.1mm or Φ3.0mm(hopcalite particle), 120 mesh(hopcalite powder) |

| Length | 2-5mm or 5-10mm or Customize (hopcalite particle) |

| Bulk density | 0 .79- 1 .0 g/ ml |

| Surface area | >200 m2/g |

| Active ingredients | Manganese based nano composites |

| CO concentration | ≤50000ppm |

| Decomposition Efficiency | ≥97%(20000hr-1,120ºC,Final result be different according to actual working conditions) |

| Working Temperature | It can be used at RT,but 100ºC-200ºC is recommended |

| Recommended GHSV | Generally between 1 000 and 100 000 |

| Service life | 2-3 years |

Advantage of hopcalite catalyst

A) Long lifetime. Xintan hopcalite catalyst can reach 2-3 years.

B) High efficiency. The active ingredient content of hopcalite catalyst is more than 85%, and the specific surface area is higher than 200m2/g, which can effectively improve the catalytic efficiency of the product.

C) High catalytic activity. The catalyst is developed with high active formula, which can efficiently convert CO to CO2.

D) Low cost. The catalyst can oxidize CO gas at room temperature.

Shipping,Package and storage of hopcalite catalyst

A) Xintan can deliver cargo below 5000kgs within 7 days.

B) 35kg or 40kg into Iron drum or plastic drum

C) Keep it dry and seal the iron drum when you store it.

D) Regeneration condition: Regeneration can be achieved by placing the catalyst at a temperature of 150-200 degrees Celsius.

Application

A) Refuge chamber

In the refuge chamber, the general humidity will be relatively high, therefore, if you want to use the CO removal catalyst, to install a desiccant at the air intake end of the catalyst, the air with water vapor first through the desiccant, so that the water vapor is absorbed and filtered, and then let the dry air through the CO catalyst layer, so that the CO gas is catalyzed into CO2.

B) Fire escape mask

When a fire occurs, a large amount of carbon monoxide gas is produced, and the CO removal catalyst (Hopcalite catalyst) can be put into the filter tank of the fire mask to convert CO into CO2.

C) Compressed air breathing equipment. Such as lightweight diving equipment.

D) High purity gas treatment

In the production of nitrogen, oxygen and other high purity gases, will produce a small amount of carbon monoxide, CO removal catalyst (Hopcalite catalyst) can treat carbon monoxide at low temperature.

Technical service

Based on working temperature, humidity, airflow and CO concentration. Xintan team can offer advice on the quantity needed for your device.

1. It is recommended that the humidity of the working environment be lower than 10%. The high humidity working environment will reduce the use effect of the catalyst and shorten the service life.

2. When humidity is over 10%, it can be used with desicant.

3. Hopcalite powder can be 150 mesh or customized, based on quantity.