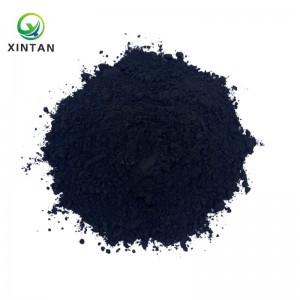

Natural Amorphous Graphite Microcrystalline graphite

Main parameters

| Model No | C(≥%) | S(≤%) | Moisture(≤%) | Ash(≤%) | Volatiles(≤%) | Size |

| XT-A01 | 75-85 | 0.03-0.3 | 1.5-2.0 | 11.5-21.5 | 3.5-4.5 | 20-50mm |

| XT-A02 | 75-85 | 0.03-0.3 | 1.5-2.0 | 21.5-11.5 | 3.5-4.5 |

1-3mm/ 1-5mm/ 2-8mm |

| XT-A03 | 75-85 | 0.3-0.5 | / | / | / | 50-400mesh |

Size: It can be customized according to requirement of customers.

Advantage of Natural amorphous graphite

a) High temperature resistance: The melting point of natural amorphous graphite is 3850±50 ℃ , the boiling point is 4250 ℃. In the metallurgical industry, the product is mainly used to make graphite crucible, in steelmaking commonly used graphite as a protective agent of ingot, metallurgical furnace lining.

b) Chemical stability: Good chemical stability at room temperature, acid resistance, alkali resistance and organic solvent corrosion resistance.

c) Thermal shock resistance: When used at room temperature, it can withstand the drastic change of temperature without damage. When the temperature changes suddenly, the volume of graphite changes little and will not produce cracks.

d) Conductive and thermal conductivity: The electrical conductivity is hundreds of times higher than that of general non-metallic ores, and the thermal conductivity exceeds that of steel, iron, lead and other metal materials. The thermal conductivity decreases with increasing temperature, and even at extremely high temperatures, graphite becomes an insulator.

e) Lubricity: The lubricating performance of graphite depends on the size of the graphite flakes. The larger the flakes, the smaller the friction coefficient and the better the lubricating performance.

f) Plasticity: Graphite has good toughness and can be made into very thin sheets.

Shipping,Package and storage

a) Xintan can deliver Natural amorphous graphite below 60 tons within 7 days.

b) 25kg small plastic bag into ton bags

c) Keep it in dry environment, It can be stored over 5 years.

Applications of Natural amorphous graphite

Natural amorphous graphite is widely used in casting paint, oil drilling, battery carbon rods, iron and steel, casting materials, refractory materials, dyes, fuels, electrode paste, and used as pencils, welding rods, batteries, graphite emulsion, desulfurizer, preservative anti-slip agent, smelting carburizer, ingot protection slag, graphite bearing and other products.